|

Michael Pullinger

How do you predict the performance of something that is composed of countless components interacting in complex ways, costs millions of dollars to build, and for which there is no 'second chance' to get it right?

Many projects are completely unique, so there are limitations to how far we can go with simple calculations or comparisons to similar projects. With no cost-effective way to build a reliable prototype for large, complex facilities, we enter the world of computer simulation. We can draw insights gained from intricate models that leverage the recent explosion in computing power.

Energy Revolution Services has used engineering simulation to help several clients develop a deep understanding of complex projects such as building energy retrofits, hybrid-renewable micro-grids, and fluid flow in hydroelectric facilities.

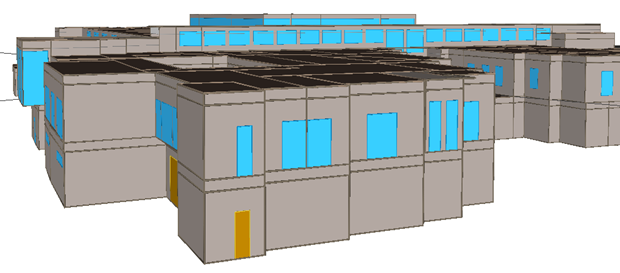

Net Zero Energy: Building Simulation Drives a Pilot Project

The design of energy efficient buildings is a key application of simulation modelling. With the advent of the BC Energy Step Code, and increased interest in maximising efficiency, Energy Revolution Services have applied our simulation expertise to dozens of recent building projects. One recent client is aiming to construct their first Net Zero Energy building: a pilot project that will set them up for success across their large portfolio of existing buildings. This building will be retrofitted to suit the needs of their new tenant, while undergoing a major refurbishment to reduce energy consumption by 80%. We developed a detailed model of the building, which allowed us to review the complex interactions between the various building components. The simulation model allowed us to quickly assess multiple scenarios, efficiently providing the best design options to the client. We reviewed various design configurations in tandem with the building designers, and estimated energy performance based on simulation results. We identified combinations of building envelope (insulation, airtightness, and windows), mechanical and natural ventilation, lighting, heating, air-conditioning, and control systems that would meet varying levels of energy performance. Through our simulation model, our client identified a preferred building configuration that met their goal of 80% energy reduction. The remaining 20% energy will be offset by a rooftop solar photovoltaic system.

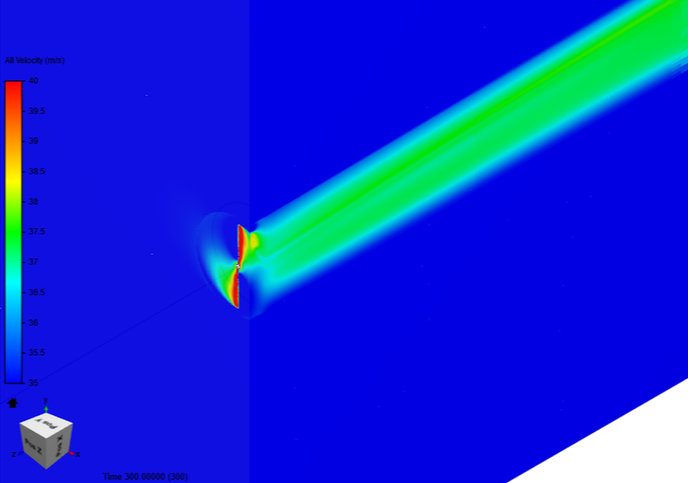

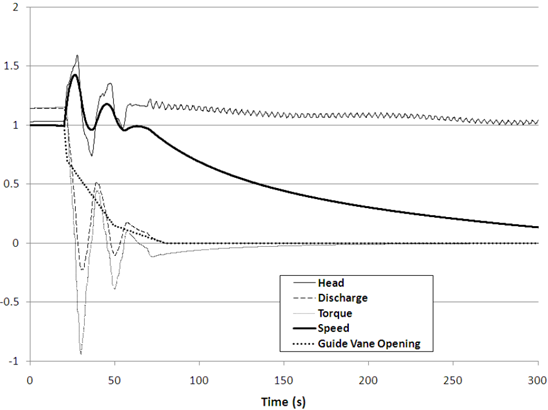

Hydroelectric Power – Quick and Safe Delivery of Energy As electrical power grids get more complex, they are also faced with the challenge of integrating more intermittent sources such as wind and solar. Wherever available, hydropower is an excellent power source to provide the flexible response the grid requires. However, every hydroelectric system will have a ‘speed limit’ imposed by the limitations of water hammer, a phenomenon that can be extremely dangerous if not handled carefully. On a recent project, our engineering team developed a flow model for a hydroelectric facility to firstly verify the capacity of the penstock (pipeline). We subsequently complete a transient analysis to identify turbine, valve and gate closure sequences that would avoid hazardous operating conditions, while simultaneously providing the quickest practical response time. Without our analysis, the required level of accuracy needed to allow system improvements would not have been achieved. Our client was able to verify that the flow conditions after completion of their project are still within their allowable limits. Furthermore, the system response time can be improved without adversely impacting the safe operation of the plant. Our engineers have worked on dozens of transient (water hammer) simulations for hydroelectric facilities, with our experience from another such project outlined in further detail here.

Pitfalls and Cautions

Simulation and modelling processes are invaluable tools for uncovering educated estimates of real-world processes. They provide a much greater range of insights and analysis than is available through simpler calculation tools. They provide much more cost-effective understanding of a problem than trying to run experiments on a physical system. But they are not the real world. Like any engineering design process, systems developed by simulation and modelling must be verified through real-world measurement and commissioning processes once constructed. A deep understanding of the physics involved, and techniques for providing ‘reality checks’ of the simulations is important. Experience is essential for providing realistic interpretations of the model limitations, assumptions, and results. We are here to provide the necessary expertise and assistance!

0 Comments

Leave a Reply. |

Categories

All

Archives

May 2024

|

Site powered by Weebly. Managed by Web Hosting Canada

RSS Feed

RSS Feed